size:

color:

technology:

Serve:

Shandong Vesteon Automotive Parts (Group) Co., Ltd consists of three manufacturing plants, vesteon tyre, vesteon alloy wheel and vesteon car batteries.

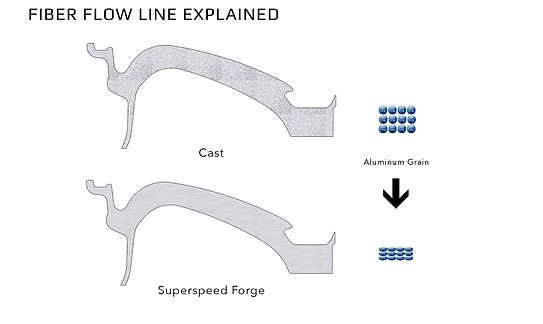

The immense 10,000 tons of pressure creates a wheel that is far stronger and stiffer with extreme weight reduction than any other forms of construction

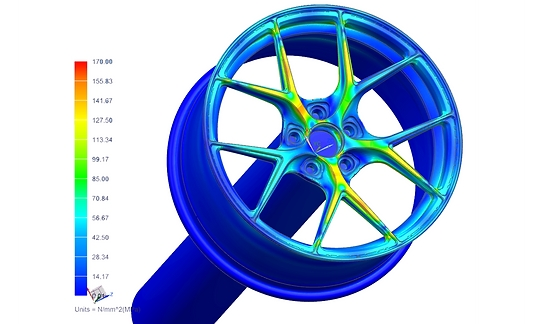

FEA (Finite Element Analysis) was conducted to find the perfect balance between weight and stiffness. Excessive weight was removed without sacrificing rigidity

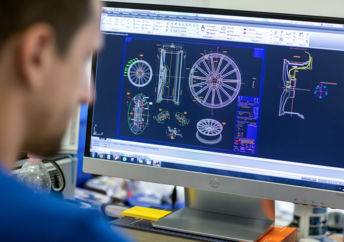

Every rim receives its final design in a CNC-controlled rolling and milling machine. The design is milled in this process step, which gives each rim its final property and look. This is followed by the removal of ridges in a deburring step done by hand. Ridges are sharp edges that are formed in a processing or manufacturing step, fraying or chippings of a metallic work piece. In total, this process takes roughly five hours.

As regards the AEZ Steam.forged series every wheel gets a top-quality ceramic finish. The rim is “fired at” by many small ceramic balls and thereby polished. Afterwards, each rim is protected with a double clearcoat as the first barrier against weather and physical influences.

© 2022 Shandong Vesteon Automotive Parts (Group) Co., Ltd. All Rights Reserved